Theme: Exploring new technologies and innovations in manufacturing

Advanced Manufacturing 2020

The Conference Series LLC Ltd organizes conferences around the world to proffer our immense pleasure and honour in extending you a warm welcome to attend Advanced manufacturing. This conference is focusing on the theme ‘Exploring new technologies and innovations in manufacturing.’ to enhance and explore the latest trends & advancements in the current technology on Advanced Manufacturing 2020 among the It professionals, mechanical engineer, and innovators along with the Industrial community to establish corporations and exchanging ideas for a better understanding of the field of Advanced Manufacturing 2020 .Advanced Manufacturing 2020 aims to provide the right stage to present stimulating keynote talks, plenary sessions, panel discussion, b2b meetings, posters, symposia, video presentations, and workshops.

Details of Advanced Manufacturing 2020, London, UK

|

Conference Name |

Place |

Date |

|

Advanced Manufacturing 2020 |

London, UK |

May 21-22, 2020 |

Conference Series invites all the experts and researchers from the Mechanical Engineering sector all over the world to attend “Future Advancement on Manufacturing: 3D Printing, Robotics & Automation“ (ADVANCED MANUFACTURING 2020) which is going to be held on May 21-22, 2020 in London, UK. ADVANCED MANUFACTURING 2020 conference includes Keynote presentations, Oral talks, Poster Presentations, Workshops, and Exhibitors. 3D Printing, Advanced Robotics and Automation Printing technology has been evolved as an interim field science and has witness a huge market potential in establishing a new business module in the field of construction, designing, automobile engineering, architecture and more. With the advent of latest technologies being integrated with huge production demands the research and development is significant and to signify the research process involved in 3D Printing & Technology.

“Future Advancement on Manufacturing: 3D Printing, Robotics & Automation” during May 21-22, 2020 in London, UK, which includes prompt keynote presentations, Oral talks, Poster presentations and Exhibitions.

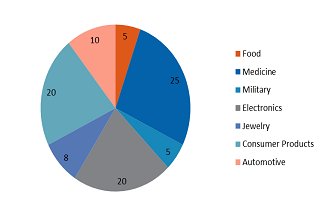

3D Printing also known as Additive manufacturing. It turns digital 3D models into solid objects by building them up in layers. The technology was first invented in the 1980s, and since that time has been used for rapid prototyping (RP). However, in the last few years, 3D printing has additionally started to evolve into a next-generation manufacturing technology that has the potential to allow the local, on-demand production of final products or parts thereof. This technology is used in the fields of jewellery, footwear, industrial design, architecture, engineering and construction (AEC), automotive, aerospace, dental and medical industries, education, geographic information systems, civil engineering, and many others.

Why to attend Advanced Manufacturing 2020?

Conferences and meetings are the only platform we can learn and exchange the knowledge. Scientists, Engineers, Directors of companies, Researches from different parts of the world come and meet at one place to share views, exchange knowledge and establish research collaborations & networking in the field of 3D Printing, Advanced Robotics and Automation .

Target Audience

1. Research Scientists

2.Students

3.Academic Faculty

4.Design Engineers

5.Mechanical engineers

6.Industrial engineers

7.Aerospace engineers

8.Architects

9.Industrialists

10.Business Entrepreneurs

11.Manufacturing Devices Companies

VISA and Invitation letter

Issue with VISA!!

Are you planning to have a professional and delightful trip to London, UK???

We believe you must be having a query regarding your VISA to Visit as a Speaker/Delegate, Tourist or Business Person to London, UK. Advancedmanufacturing2020 committee will be happy to help you in all regards to plan your trip to Spain. Here is the simplest way to know the process for your Visa Approval. Kindly register for the conference at the earliest and drops us an email at advancedmanufacturing24@gmail.com and avail the official invitation letter from us and attend this event ahead with a closer step for approval of your VISA.

Register/enroll here to get an official invitation letter:

https://manufacturing.annualcongress.com/registration.php Processing time for VISA applications may vary depending on the office and the time of the year. Delegates/Attendees are encouraged to submit their visa applications well in advance of the date of the event at a VISA Application Centre or online E-applications, including all supporting documents.

Track 1: Advances in 3D Printing & Additive Manufacturing Technology

3D printing is a form of Additive manufacturing is a process of making three dimensional solid objects by laying down successive layers of material from a digital file. It is also known as rapid prototyping. According to Standard Terminology for Additive Manufacturing Technologies, The American Society for Testing and Materials (ASTM) group “ASTM F42 – Additive Manufacturing” developed a set of standards that classify the Additive Manufacturing processes into some categories.

Stereolithography

Fused deposition modelling

Selective laser sintering

Multi-jet modelling

Electronic beam melting

Selective laser melting

Digital light processing

Laminated object manufacturing

Powder bed and inkjet head 3D printing

Composites Manufacturing

Track 2: Applications of 3D Printing in Health Care & Medicine

3D Printing has been applied in medicine since 2000s. For manufacturing of custom pros-thetics and dental implants it was first used and then onwards the medical applications for 3D Printing has evolved significantly. By the use of 3D printing we can produce exoskeletons, windpipes, jaw bone, bones, ears, blood vessels, vascular networks, tissues, eye-glasses, cell cultures, stem cells and organs. The current medical applications of 3D Printing can be categorized into a number of categories that are creating im-plants, tissue and organ fabrication, prosthetics and pharmaceutical research concerning drug discovery and anatomical models.

Selective laser melting

Bio printing tissues and organs

Anatomical models for surgical preparation

Customized implants and prostheses

Drug delivery devices and dosage forms

Challenges in building 3D Vascularized organs

Cancer Research

Bone repair

Track 3: Innovations in 3D Printing

3D Printing technology is constantly evolving and definitely has a considerable measure in its pocket for the future. The level of customization that the technology offers opens up the door for its application in numerous enterprises, permitting it to take care of a considerable measure of issues. This review will abandon you with a look at work in advance in the 3D Printing Industry.

3D Printed Food

3D Printed shoes

3D Printed organs

3D Printing Redefining Air travel

Consumer 3D Printing

Track 4: 3D Printing Materials

A wide range of materials can be utilized for 3D printing, for example, ABS plastic, PLA, polyamide (nylon), glass filled polyamide, stereo lithography materials (epoxy gums), silver, titanium, steel, wax, photopolymers and polycarbonate. The materials accessible for 3D printing have progressed significantly since the beginning of the innovation. There is presently a wide assortment of various material types, which are provided in various states. Particular materials are now generally produced for particular stages performing dedicated applications with material properties that more precisely suit the application. The energy around the promise of 3D printing has opened the floodgates. New printers are being created each day to print a wide range of materials from plastics, metals, composites, and cement, to organic materials, paper, and food.

Plastics (polyactic acid, acrylonitrile butadiene styrene, polyvinyl alcohol plastic)

Powders (polyamide, alumide, multicolour)

Resins( high detail resin, paintable resin, transparent resin)

Other materias (Titanium, stainless steel, bronze, brass, silver, gold, ceramics)

Track 5: Metal 3D Printing

Metal 3D printing also known as Metal Additive Manufacturing (AM) and Direct Metal Laser Sintering (DMLS) is the procedure by which parts are fabricated by a laser fusing together high performance metals, layer by layer. Metal printing processes like powder bed fusion, metal binder jetting, and directed energy deposition developed at an explosive pace. There are various sorts of metal 3D printing that each have their own particular advantages. Here are some of the most common types used to digitally craft metal objects.

Selective Laser Melting (Powder Bed Based)

Selective Laser Sintering (Powder Bed Based)

Robocasting

Binder Jetting and Inkjet 3D Printing

Binder Jetting and Inkjet 3D Printing

Track 6: Benefits of 3D Printing and Technology

3D Printing, whether at an Industrial, local or individual level, brings a large group of advantages that conventional strategies for fabricate (or prototyping) simply can't. 3D Printing forms take into account mass customisation — the capacity to customize items as per individual needs and prerequisites. When you utilize a 3D printer over more conventional manufacturing Processes, the list of coming about advantages is entirely long. From significant cost investment funds and quicker generation times to more imaginative opportunity and a diminished carbon impression, there is no deficiency of focal points with these manufacturing methods. A 3D printer diminishes your overhead expenses altogether, and in more ways than one. Initially, it eliminates material expenses. Rather than utilizing a major square of plastic, metal or other material and removing the product out of it we can utilize just the materials totally essential for the construct (added substance producing). This not just cuts your forthright expenses for materials, it also reduces the funds you'd typically spend on transporting and discarding that waste.

Quick production

Cheap Manufacturing

Better quality

Less waste

Accessibility

Sustainability

New shapes and structures

New combinations of materials

New business models

Track 7: 3D Printing Technology Impact on Manufacturing Industry

3D printing, or additive manufacturing, has been the concentration of some solid talks in the manufacturing industry in the most recent couple of years. While the idea of 3D printing has been around for some time, new progressions in the innovation have begun to bring down the cost of the procedure to levels that make it more achievable for general manufacturing use. The procedure of utilizing specialized equipment to gather an object layer by layer has some one of a kind and fascinating points of interest over traditional manufacturing.

Material cost savings

Improvement to incremental cost calculations

Strategy transformation

Track 8: 3D printing in Biomaterials

3D bio printing is the process of making cell designs in a bound space utilizing 3D printing technologies, where cell capacity and suitability are saved inside the printed build. 3D bioprinting contributes to huge advances in the medical field of tissue engineering by taking into account research to be done on inventive materials called biomaterials. Biomaterials are the materials adjusted and utilized for printing three-dimensional articles. Some of the most prominent bioengineered substances are normally stronger than the normal real materials, including soft tissue and bone. These constituents can act as future substitutes, even upgrades, for the original body materials.

Tissue engineering

3D Bio plotting

Cell encapsulation

Rapid prototyping

Photo polymerization

Biodegradable and bioresorsable polymers

Track 9: 3D Bio printing

3D Bio printing is the way towards making cell designs in a restricted space utilizing 3D printing technology, where cell capacity and viability are saved inside the printed build. 3D bioprinting adds to huge advances in the medicinal field of tissue engineering by allowing for research to be done on innovative materials called biomaterials. In bioprinting, there are three major types of printers that have been utilized. These are inkjet, laser-assisted, and extrusion printers. 3D Bio printers are streamlined to have the capacity to print skin tissue, heart tissue, and veins among other essential tissues that could be appropriate for surgical treatment and transplantation.

3D Bioprinting of Tissues and Organs

Skin 3D Bioprinting

3D bioprinting of Neural stem

3D bioprinting of Cell-Laden Microcarriers

3D bioprinting of human chondrocytes

Bioprinting of 3D hydrogels

3D bioprinting of cartilage

3D bioprinting of Ear

3D bioprinting of Aortic valves

Track 10: 3D Printing Future Technology

3D Printing is moving in several directions as of now and all signs are that it will keep on expanding in numerous ranges later on. The absolute most encouraging zones incorporate medical applications, custom parts substitution, and customized buyer items. As materials enhance and expenses go down, different applications we can barely imagine today will become possible.

Directed energy deposition

Sheet lamination

Material Extrusion

Vat photo polymerization

Material jetting

Binder jetting

Powder bed fusion

Track 11: Automation

Robotics is the branch of technology that deals with the design, construction, operation, and application of robots and the use or introduction of automatic equipment in a manufacturing or other process or facility is automation.Related Journals of Robotics: Journal of Operations Management, MIS Quarterly: Management Information Systems, IEEE Communications Magazine, IEEE Wireless Communications, Wiley Interdisciplinary Reviews: Computational Molecular Science, IEEE Transactions on Industrial Electronics, Enterprise Information Systems, IEEE Transactions on Information Theory

Track 12: Behavior-based systems

Most Behavior-based systems are also reactive, which means they need no programming of internal representations of what a chair looks like, or what kind of surface the robot is moving on. Instead all the information is gleaned from the input of the robot's sensors. The robot uses that information to gradually correct its actions according to the changes in immediate environment. Behavior-based robots (BBR) usually show more biological-appearing actions than their computing-intensive counterparts, which are very deliberate in their actions. A BBR often makes mistakes, repeats actions, and appears confused, but can also show the anthropomorphic quality of tenacity. Comparisons between BBRs and insects are frequent because of these actions. BBRs are sometimes considered examples of weak artificial intelligence, although some have claimed they are models of all intelligence.

Track 13: Biomechanics and Robotics

Biomechanics relationship between external forces (e.g. body weight and external environment) and internal forces (e.g. active forces generated by muscle contraction and passive forces exerted on local structures by bones and joints) and the resultant effect of these forces on body movement. Biomechanics is the study of the structure and function of biological systems such as humans, animals, plants, organs, and cells by means of the methods of mechanics.

Track 14: Industrial Robotics

An industrial robot is defined as an automatically controlled, reprogrammable, multipurpose manipulator programmable in three or more axes.

Related Journals of Industrial Robotics: International Journal of Machine Tools and Manufacture, International Journal of Production Economics, Production and Operations Management, CIRP Annals - Manufacturing Technology, IEEE Industrial Electronics Magazine, International Journal of Robust and Nonlinear Control, Automobile Engineering Journals, Electrical & Electronic Journals, Lovotics Journals, Mechanical Engineering Journals

Track 15: Intelligent Robotics

Lovotics, as a discipline, aims to elevate the Social Robotics and Human Robot Interaction towards affection and friendship between the robot and the human partner. The aim of the journal is to serve as a platform for researchers across the world to share their latest research, development and innovation in the field of Lovotics, for the benefit of the robotics community and with the vision to contribute for the betterment of the society.Intelligent robotics are the robots that functions as an intelligent machine, that is, it can be programmed to take actions or make choices based on input fromsensors.

Related Journals of Intelligent robotics: Nature Nanotechnology, IEEE Communications Surveys and Tutorials, Digest of Technical Papers IEEE International Solid-State Circuits Conference, IEEE Journal of Solid-State Circuits, IEEE Communications Magazine, IEEE Wireless Communications, IEEE Journal on Selected Areas in Communications, Automobile Engineering Journals, Electrical & Electronic Journals, Lovotics Journals, Mechanical Engineering Journals.

Track 16: Lovotics

Lovotics, as a discipline, aims to elevate the Social Robotics and Human Robot Interaction towards affection and friendship between the robot and the human partner. The aim of the journal is to serve as a platform for researchers across the world to share their latest research, development and innovation in the field of Lovotics, for the benefit of the robotics community and with the vision to contribute for the betterment of the society.

Track 17: Medical Robotics

Replacing humans with robots in personal assistance tasks is one of the more prominent goals of Medical robotics. In addition to promoting the right to health care, these robotic systems may bring about novel ways of protecting the dignity of both patients and their human assistants, by taking on unpleasant tasks (e.g., house cleaning), and allowing disabled or elderly people to perform basic everyday tasks (e. g., cooking, eating or self-cleaning tasks) without having to rely on human assistance.

Related Journals of Medical Robotics: Annual Review of Biophysics,Quarterly Reviews of Biophysics, Biochimica et Biophysica Acta - Gene Regulatory Mechanisms, Biomaterials, Biochimica et Biophysica Acta Bioenergetics, Biophysical Journal, Structural Health Monitoring, Biosensors and Bioelectronics, Automobile Engineering Journals, Electrical & Electronic Journals, Lovotics Journals, Mechanical Engineering Journals

Track 18: Neurorobotics

Neurorobotics are the robotic devices that have control systems based on principles of the nervous system. These models operate on the premise that the “brain is embodied and the body is embedded in the environment.

Related Journals of Neuro Robotics Foundations and Trends in Machine Learning, IEEE Transactions on Pattern Analysis and Machine Intelligence, International Journal of Computer Vision, ACM Transactions on Intelligent Systems and Technology, IEEE Transactions on Fuzzy Systems, Journal of the ACM, IEEE Transactions on Neural Networks and Learning Systems, Information Sciences, Automobile Engineering Journals, Electrical & Electronic Journals, Lovotics Journals, Mechanical Engineering Journals

Track 19: Robotic Rehabilitation

Robotic Rehabilitation is a field of research described to understanding and augmenting rehabilitation through the application of robotic devices. Rehabilitation robotics includes development of robotic devices tailored for assisting different sensor motor functions.

Related Journals of Robotics Rehabilitation: IEEE/ASME Transactions on Mechatronics, IEEE Transactions on Robotics, IEEE Transactions on Computational Intelligence and AI in Games, IEEE Transactions on Industry Applications, Mechanical Systems and Signal Processing, IEEE Transactions on Control Systems Technology, Annual Reviews in Control, Journal of Guidance, Control, and Dynamics, Automobile Engineering Journals, Electrical & Electronic Journals, Lovotics Journals, Mechanical Engineering Journals

Track 20: Telerobotics

Telerobotics is the area of robotics concerned with the control of semi-autonomous robots from a distance, chiefly using Wireless network (like Wi-Fi, Bluetooth, the Deep Space Network, and similar) or tethered connections. It is a combination of two major subfields, teleoperation and telepresence

Related Journals of Tele Robotics: IEEE Transactions on Fuzzy Systems, Journal of the ACM, IEEE Transactions on Industrial Electronics, Information Sciences, IEEE Transactions on Systems, Man, and Cybernetics, Part B: Cybernetics, IEEE Transactions on Automatic Control, IEEE Transactions on Industrial Informatics, Automatica, Journal of Machine Learning Research, Automobile Engineering Journals, Electrical & Electronic Journals, Lovotics Journals, Mechanical Engineering Journals

Track 21: 5G for Manufacturing

5G technologies provide the network characteristics essential for manufacturing. Low latency and high reliability are needed to support critical applications. High bandwidth and connection density secure ubiquitous connectivity. These are requirements that manufacturers currently rely on fixed-line networks. These include industrial control and automation systems, planning and design systems, and field devices.

5G networks offer manufacturers and telecom operators the chance to build smart factories and truly take advantage of technologies such as automation, artificial intelligence, augmented reality for troubleshooting, and the Internet of Things (IoT).

With 5G, operators can create new revenue streams. Alongside energy and utility, manufacturing represents one of the most significant sectors for new revenue potential for operators addressing industry digitalization with 5G technologies. According to the Ericsson study, the 5G Business Potential, the expected addressable market in 2026 will be USD 113 billion, a substantial 7 percent potential revenue growth from current service revenue forecasts.

The AMA cluster enables a wide range of stakeholders, such as researchers, technologists, business and development executives to gain information that can be used to better develop or exploit key technologies impacting advanced manufacturing. Our analysts have expertise in vital areas of advanced manufacturing, including 3D printing, automation hardware, software, data communications in manufacturing environments, materials joining, collaborative robotics, and additive manufacturing.

Our expertise is honed through reporting and analysis of key developments and through preparation of reports and client-centered research. We are able to identify key developments in manufacturing technologies and, more importantly, evaluate their value and market prospects..

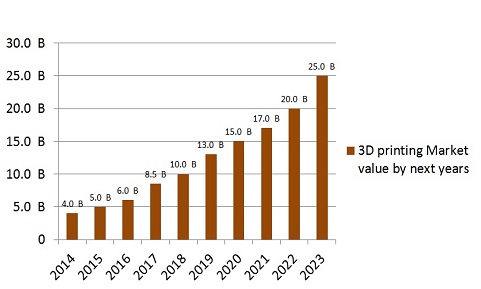

The overall 3D printing market is expected to grow from USD 9.9 billion in 2018 to USD 34.8 billion by 2024, at a CAGR of 23.25%. Ease in the development of customized products, reduction in manufacturing cost and process downtime, government investments in 3D printing projects, and development of new industrial-grade 3D printing materials are the key factors driving the growth of this market.

Service offerings to hold largest share of 3D printing market in 2018

The service segment accounts for the largest share of the 3D printing market based on offering. The projected growth of the market for service is attributed to the expected increase in the demand for custom design and manufacturing. The market for 3D printing has been growing at a significant rate with rapid progress in the verticals such as healthcare (including medical, orthopedic, and dentistry), aerospace, and automotive as these are the early adopters of the technology. However, with the advancement in the printing technology and materials, the 3D printing service sector is garnering significant traction as a source of profit generation, compared to printers and materials.

Power bed fusion process to hold largest share of 3D printing market in 2018

Power bed fusion process accounts for the largest share of the market. The growth of the market for power bed fusion process can be attributed to the ability to produce complex geometries, high-feature resolution, good strength, and decent surface finish. The 3D printing procedures based on powder bed fusion process in the aerospace, automotive, healthcare, and engineering verticals more commonly use technologies such as direct metal laser sintering (DMLS), electron beam melting (EBM), selective heat sintering (SHS), selective laser melting (SLM), and selective laser sintering (SLS) are most commonly used for the development of functional parts.

Prototyping to lead 3D printing market in terms of size during forecast period

Prototyping application accounts for the largest share of the 3D printing market. 3D printing helps produce prototypes and models from 3D computer-aided design (CAD). This helps several companies to reduce wastage during prototype transitions in traditional manufacturing and also helps them to bring down their operational costs. 3D printing also enables the quick production of cost-efficient prototypes based on the customer requirements regarding the geometry of the structure, accuracy, and well-defined smoothness of the products used in any industry.

Key Market Players

A few major companies in the market are Stratasys (US), 3D Systems (US), EOS GmbH (Germany), GE Additive (US), Materialise (Belgium), SLM Solutions (Germany), ExOne (US), Voxeljet (Germany), HP (US), and EnvisionTEC (Germany). Inorganic growth strategies such as agreements, partnerships and collaborations are the focus area of many of the above.

Prominent players have adopted agreements, partnerships, and collaborations, followed by product launches and developments, as the key business strategies to strengthen their positions in the 3D printing market. For instance, in September 2018, Stratasys (US) extended its collaboration with Team Penske (US) for offering FDM AM (by using Fortus 380mc Carbon Fiber Edition and Stratasys F900 Production 3D printers) for advance car testing, and production of prototypes and functional parts based on advanced materials, such as carbon fiber-filled Nylon 12.

Major Market Developments

- In September 2018, EOS GmbH (Germany) launched EOS M 300-4 metal 3D printer. The printer features 4 lasers that offer variable laser power sources, from 4 × 400, to a mixed set-up of 2 × 400 and 2 × 1,000, up to 4 × 1,000 Watt laser power.

- In December 2017, Arcam, a subsidiary of GE Additive (US), opened a manufacturing facility at Härryda, Sweden. The facility is expected to strengthen its machine production capacity and allow for a more collaborative set-up within the company, uniting logistics, research and development, services, and operations.

- In January 2017, 3D Systems (US) acquired Vertex-Global Holding B.V. (Netherlands), a provider of dental materials worldwide, which offers products (photopolymer, thermoplastic, polymer, and monomer materials) under the Vertex and NextDent brand for traditional and 3D printing dental applications.

Robotics:

Robotics is in great demand. Japan's Artificial Intelligence showcase is assessed to develop from JPY 3.7 trillion of every 2015 to JPY 87 trillion by 2030. In 2015, Artificial Intelligence answers for the discount and retail sectors were valued at JPY 1.45 trillion, or about 39% of the complete market esteem, including the biggest Artificial Intelligence sub-section. By 2030, the transport sector is required to develop to JPY 30.48 trillion. Counting driverless autos, together these two areas will have a market evaluation of JPY 42.65 trillion or 49% of the total market value.

The mechatronics and robotics programs market can accomplish an excellent cost of USD 15 billion amid the estimated time frame of 2018 to 2023. The mechatronics and robotics courses are anticipating a rise of 15%, states Market Research Future. The robotics courses are making remarkable force because of its fruitful development in informative organizations. Robotics courses are earning accolades from primarily the automotive sector.

Little and medium-size organizations are discovering incredible utilization of mechatronics and robotics courses in their day by day production. Their basic concern for these areas is to limit operational value, while maintaining eco-friendly standards and compliance with supervisory requirements set by governments. Meanwhile, it improves business tasks and influences them increasingly proficient which can make significant open doors for the mechatronics and apply autonomy courses to advertise.

Conference Highlights

- Advances in 3D Printing & Additive Manufacturing Technology

- Applications of 3D Printing in Health Care & Medicine

- Innovations in 3D Printing

- 3D Printing Materials

- Metal 3D Printing

- Benefits of 3D Printing and Technology

- 3D Printing Technology Impact on Manufacturing Industry

- 3D printing in Biomaterials

- 3D Bio printing

- 3D Printing Future Technology

- Automation

- Behavior-based systems

- Biomechanics and Robotics

- Industrial Robotics

- Intelligent Robotics

- Lovotics

- Medical Robotics

- Neurorobotics

- Robotic Rehabilitation

- Telerobotics

To share your views and research, please click here to register for the Conference.

To Collaborate Scientific Professionals around the World

| Conference Date | May 21-21, 2020 | ||

| Sponsors & Exhibitors |

|

||

| Speaker Opportunity Closed | |||

| Poster Opportunity Closed | Click Here to View | ||

Useful Links

Special Issues

All accepted abstracts will be published in respective Our International Journals.

- Journal of Applied Mechanical Engineering

- Research & Reviews: Journal of Engineering and Technology

- Journal of Global Research in Computer Science

Abstracts will be provided with Digital Object Identifier by